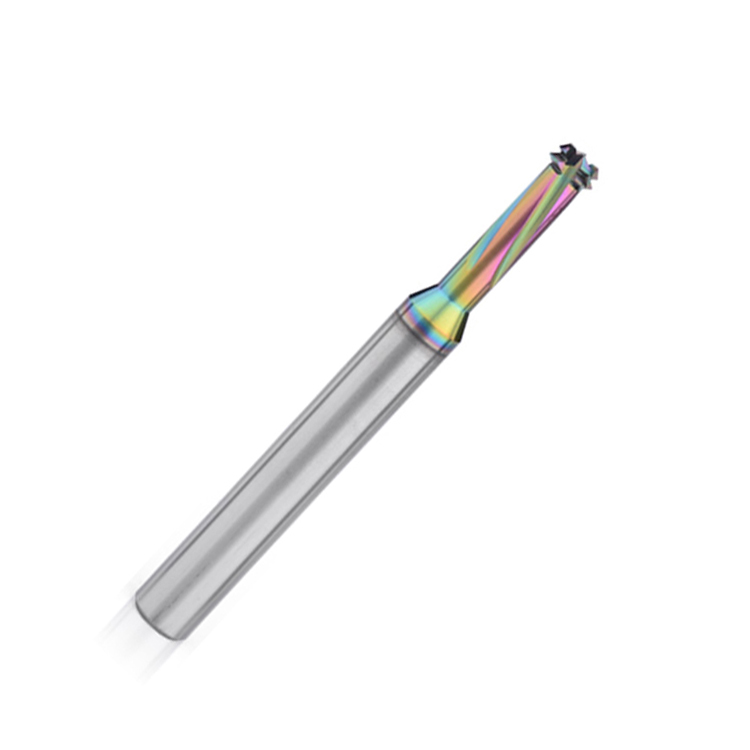

THREAD MILLS

Carbide thread mills is one of the threading tools, made of ultra-fine-grain carbide material with TIALN coating, and it is processed by three-axis linkage machining center. Compared with the traditional thread machining method, thread milling has great advantages in machining accuracy and efficiency, which is not limited by the thread structure and thread rotation. For example, a thread milling cutter can process a variety of internal and external threads.

Solid carbide thread milling cutter is suitable for small and medium diameter thread milling of steel, cast iron and non-ferrous materials, with smooth cutting and high durability. Thread milling with different coatings are used for machining different materials, widely used in automotive, aerospace, medical, engineering, etc.

CRONAMETAL as the brand of CRO Precision Tools, which is a leading carbide thread milling factory in China, manufacturing an extensive thread mills products, including single profile thread mills, miniature thread mills, full profile or helical thread mills, combined drilling thread mills, etc. Thread types are ISO, 55°, UN, W, BSPT, NP, NPT, NPTF, NPS, NPSF, etc.

There are some advantages of carbide thread mills:

a. More stable

For small-diameter threading, especially for high-hardness and high-temperature materials, thread milling cutter cuts into the material gradually, generate small cutting force to avoid breaking tools.

b. Higher Precision/Accuracy

Thread milling cutters use helical interpolation to ensure accuracy, so it is only necessary to adjust the program to easily obtain the required high-precision threads.

c. More efficient

Use one tool for threading holes of the same pitch and different diameters

d. Better finishing surface

Since the thread milling cutter is made of tungsten carbide material, its small cutting force greatly improves the surface finish of the machined thread.